The Rollmaster true roller timing sets have been available for a number of years now for the Ford Y-Block family of engines. These have been a big plus for those engine builders that go to the extra effort of degreeing in the camshafts as the lower crankshaft gear is keyed for nine different camshaft positions. Before these Rollmaster timing sets came to market, degreeing in the camshafts on the Y involved offset keys or broaching new keyway slots in the crankshaft or camshaft timing gears. The offset keys were always questionable strength wise regardless if the valve spring pressures were increased or not. The practice of broaching new keyway slots in the gears is not an exact science when it comes to getting the new keyway in the exact ‘right’ location. The Rollmaster timing sets eliminates those prior difficulties.

What showed up in this shop last year were two different Ford Y engines with Rollmaster timing chain sets that were on the verge of coming apart. The roller chain side plates that hold the links or pins in place were coming off of the chains. These two engines were in the shop for other reasons and the side plates that hold the links being missing from the chains had not become an issue in causing any kind of catastrophic failure in that area …. yet. The first engine this was noticed on had a side plate simply laying in the front of the oil pan when the timing cover was removed which was an immediate alert that something was amiss. Had it not been for the appearance of that piece laying in the oil pan, there’s a good chance that missing side plate may have gone un-noticed as that side plate had come loose from the chain at the back or block side of the chain. Upon removing the chain from the engine, it’s noticed that a second side plate is also missing from the back side of the chain. Searching around in the oil pan finds that other missing side plate. If not noticing that side plate lying in the pan and unless the chain was being removed, those missing side plates would have likely have gone unnoticed. For that particular engine, the chain was simply replaced with a new timing set and everyone was left wondering why there was a failure on that chain. That timing set is simply tagged accordingly and stored on a shelf for the time being as it’s an anomaly without an immediate reason for the failure.

It’s less than six months later when another Y comes into the shop in short block form from an estate sale as a potential engine build for a customer. That engine also has a Rollmaster timing set installed and a cursory examination finds a side plate missing from one of the links. Again, this missing side plate is on the back or block side of the timing chain. It’s not going to be noticed unless you are looking for it. Same drill as before as the timing set is replaced with a new one and the camshaft is appropriately re-degreed in.

This is two potential chain failures in a short period of time which begs the question “What’s going on?” A major clue is that the missing side plates are from the backsides of both chains. There are no obvious wear marks on the block or protrusions that could be hitting the chain so that’s ruled out. The upper and lower gears are also in vertical alignment with each other so that’s not a consideration either. A more thorough examination of the chains on their backsides shows several other side plates on the verge of coming loose. First thoughts are maybe a defective chain but that’s lowered on the list of probable reasons when looking at the history of both engines. Both engines had been built elsewhere and based on the lower crankshaft gears being in non-zero keyway locations, both engines had had their camshafts previously degreed in. In looking at the chains in detail, there are only certain areas of the chain where the roller link pins are barely holding the side plates in place which is driving to the conclusion that the chains were damaged during the prior cam degree in operations.

After a round table discussion, here’s the most probable scenario as to what happened. These are two different engines and from two different locales so we are dealing with two different individuals or engine builders. These builders had installed the timing sets and after initially degreeing them in found that the camshafts needed to be moved in which to re-phase them. To make this happen, the upper and lower gears were removed or pried forward by using some kind of wide bladed pry bars and those pry bars put pressure directly on the roller link pins. Those pins were then simply pressed forward with pressure exerted against them and allowed the pins to be pushed so that the pins were now flush with the side plates. At that point, the pressure is adequate enough to then force the timing gears forward in which to remove the chain and relocate the crank gear position in which to change the cam timing. Once that operation was complete, the side plates were not pushed off the pins but were only being marginally held in place at that point in time. The roller pins are effectively now flush with the side plates with only a minimal amount of crimp or crush holding the side plates in place. Once the engines are up and running, the major amount of crimp on the pins that holds those side plates in place was gone and the side plates simply fell off the pins and into the oil pan. Hard to say exactly how long it took for those side plates to fall off as both engines had some miles on them. It was mentioned that there was as much as 3500 miles on one of them. The exact mileage or run time on the other engine is unknown but based on the cylinder and bearing wear, it was low mileage also.

Having worked with roller timing chains on other engines for a good number of years, this was the first instance I’ve been exposed to with side plates coming off of the roller pin links. And in this instance, it was two different Ford Y engines in a very short period of time. But it does show a weakness in the roller link type of timing chains if particular care is not taken when removing them from the engine. The same could be said for also installing them if pressure is put on the chains rather than the gears to get them pushed into place.

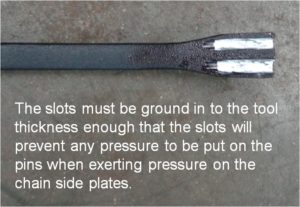

When Joe Craine saw this problem, he had a quick solution for removing the gears for cam timing adjustments. He obtained some wide bladed pry bars and modified them with recessed slots on their ends. These slots fit around the pins and allow the gears to be pushed forward without any pressure on the pins and only on the side plates.

Click on pictures for larger images.

You still have to be careful in the placement of these modified pry bars when placing them on the chain but when placed properly behind the chains, it eliminates the possibility of the pins being used as the point of contact for pushing the gears forward. In lieu of making some slotted bars for removing the chain and gears forward, simply catching the side plates at their edges will also work but this does not give the same working surface area that’s presented when using Joe’s modified tools.

With all that being said, just be careful in how those chains are being removed and avoid putting any pressure on the roller link pins.

Until next time, Happy Y Motoring. Ted Eaton.

Originally published in The Y-Block Magazine, Issue #151, Mar-Apr 2019